Mangalore, October 29: Efforts are made to establish Coconut Development Board which has not been implemented yet in Karnataka state which stands second in coconut cultivation in the country.

Kerala stands first in coconut crop production and coconut secondary product production. Even though our state stands second in coconut production, it is in the tenth position in the production of secondary products. Technically the achievement is zero. For the same reason, coconut crop has not provided the expected income or benefit for many years.

Lack of organization:

Karnataka which is first in the production is lagging behind in the technology of making the best out of it. The main reason behind the fall is due to the lack of sufficient demand and organizational effort from the peasants for technology.

such an effort has seen a move now. Simi, the technical Director of the State Board of coconut production has said, by organising a weeklong camp at of horticultural center in Thumbe, Bantwal the confidence must be rooted among the coconut growers.

He opined that, the citizens and petty farmers must come forward to utilize all the benefits provided by the board which is listed by him.

Facilities:

The Farmers who possess minimum of ten coconut trees can avail the benefits.

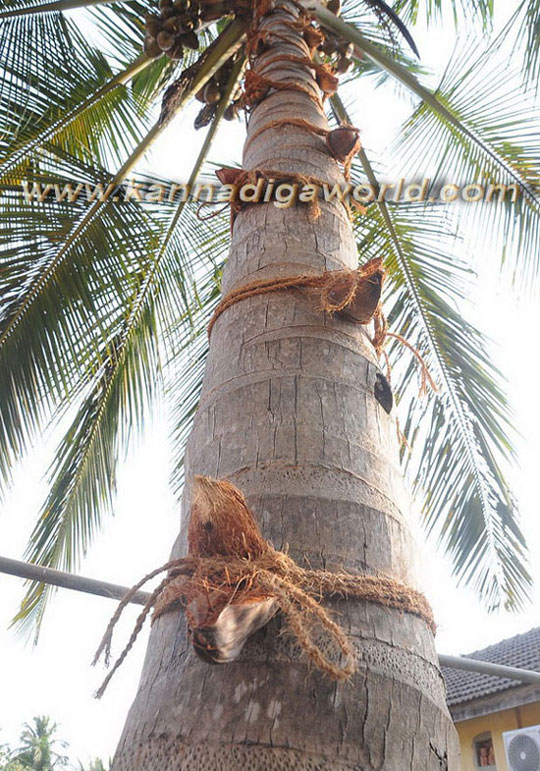

Subsidy for tree climbing machine:

subsidy amount for the fertilizer used for the tree.

Providing various technologies to process coconut fibre, water and pulp in order to gain more profit.

Small scale industry of oil extraction from coconut pulp, residue segregation and utilization of coconut pulp powder, chips and sub-products.

Toddy extraction from coconut spade.

Soft drinks, jaggery, sugar, honey, etc are already being produced from toddy.But in limited numbers.

Kalparasa (Toddy):

It is the coconut tree fluid. It is pure as tender coconut. It is the most modern first unit in the country. It is implemented at horticultural area in Thumbe, Bantwal during the year 2011-12.

After two long years of facing technical glitch, it has been launched through Palakkad Coconut Development Board.

The toddy soft drink is available in small packet containers at hop-coms unit in Mangalore

Wide opportunity:

Already toddy has an international demand. Sri Lanka is credited for popularizing the drink to international fame. Coconut Development Board in Palakkad, Kerala is popularising the drink in Kerala.

Joint management:

Under the joint organisation of the Department of Horticulture, Coconut Development Board, Palakkad coconut development the company has consented for the operation of the unit, is now equipped for distributing the product to the public after obtaining the consent from the extraction marketing association.

2 thousand Litres capacity:

This unit has a maximum of two thousand litres of storage and processing capacity per day.

Minimum of hundred extractors, same number of helpers, for processing, marketing and distribution; approximately fifty staff is required.

At least 800 coconut trees should be available. An average of 3 litres of fluid is available from plant. Work is available throughout the year. Overall this unit can employ 300 persons at present.

Experimental Unit :

This is the first experimental unit. It will be a boon for the countryside coconut farmers after further improvement. It may provide large-scale employment in agriculture sector.

Government Project: 1crore grant

In order to promote the coconut farmers, this government project is chalked out. The machinery for the new unit is stationed. In the state to advance letter of 2011-12 Rs 1 crore fund was released for this. An additional assistance of Rs 1 crore is hoped to be assured of release by the government, revealed the assistant director.

Machinery worth Rs 80 lakh will be stationed at four thousand square foot unit at Thumbe. It can produce 2,000 litres daily.

New revolution:

It is believed that Neera will make a new revolution in the market.

Adulteration is impossible:

Neera drips out from the spade of coconut is a non-intoxicated, unadulterated, yummy flavoured drink. Neera can arrest ones thirst, will grow into king of soft drinks in future.

Neera collection centre is easy to get started which is similar to milk centres.

The coastal district is the cradle of coconut trees where the Neera industry can be further established.

Scheduled cost of a litre of Neera is Rs 130.

Neera or toddy is also called as Kalparasa.

During 2002, the experimental production of Neera was successful under the technical guidance of the DFRL Mysore. Due to legal litigation, the functioning got delayed.

Neera is a healthy drink which contains 85% water, rest of which comprises sugar, and proteins. Neera can be sold directly without processing. The kasargod CPCRI has innovated unique Toddy collection equipment. The quantity of toddy collection increases during monsoon and reduces by summer.

A person can collect 30-50 litres of toddy daily from tree and can collect toddy from 20 trees whole day.

The products such as jaggery, sugar and candy can be prepared from Toddy.

Market price of a litre of Milk is 28Rs. A litre of soft drink begins from 30 Rs.

Some soft drinks are not good for health but still we continue to sip it. But toddy has positive advantages over these. Hence Toddy was titled as “King of Drinks”.

Details of the unit:

The toddy private unit was permitted at Orissa in 2005. Even private unit are run at Tamilnadu and Kerala. Similar unit is situated in Kerala under the Government sponsorship, revealed the departmental sources.

Benefits:

If the toddy units are begun throughout the state, then coconut may get good price in the market. If it is successfully implemented, then it may provide employment to lakhs of citizens.

Coconut may get a stable price in the market and the melaybugs (Nusipeede) disease may reduce.

It may draw the attention of educated youth, providing employment to many.

Toddy can be extracted from palm and other trees of the same family.

Components of Neera :

Starch and sugar 98.76, protein 0.2, moisture 0.7, fat 0.04, calcium 58.07, phosphorus 5.04, iron 1.4, Vitamins 396.

Producing countries

India, Shri Lanka, Africa, Malaysia, Tahiland, Manyanmar countries extract toddy and use it since a long time.

Future Project:

In the future project, the local framers and the toddy collectors will be trained and these units will be extended. It intends to provide additional benefits to the coconut growers by toddy extraction.

Already the locals are trained on this.

Toddy collection is excluded from the exercise law and is elusive of in-toxic substance throughout the districts of Dakshina Kannada and Udupi. But the other districts of the state have a ban by the exercise rules.

For the next three years, it has been decided to carry on the management of Thumbe unit by the coconut growers company, Palakkad.

In the coming three years, it has plans to train the locals, quality improvement, and see through it that the processing will achieve proper profit. Along with this, it has the responsibility of handing over this unit to the coconut grower’s federation.